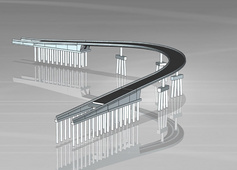

Viaduto, Fly-over

In the framework of new construction of the luxury shopping mall “Complexo WTorre JK” in the business district Morumbi,the access situation of Avenida Presidente Juscelino Kubitschek onto Marginal Pinheiros/Avenida das Nações Unidas, one of São Paulo’s main traffic axes, was newly designed. To directly connect Av. Kubitschek to The superordinate traffic lane of Av. das Nações Unidas a new flyover was built. The highly bent prestressed concrete bridge, forming a curve in the ground plan (inner radius 55m) and a crest in the elevation, holds two lanes. The structure was designed semi-integrally with fixations at both abutments and dynamic abutment formations. The span widths of the 5-span structure are around 28 m and at maximum 35 m. The total length of the fly-over including ramps amounts to around 274 m.

Particularities

Demanding design, narrow alignment radius of 65 m; longitudinal incline of tangent 8%; variable transverse incline (i.e. spatial bend); superstructure with perforated sheet panels and LED lighting

- complete, continuous 3D design from the draft to the final design in one model (incl. form finding and construction variants)

- establishing of a construction process simulation in the context of fitting the bridge into an 11-lane city highway in complicated spatial and traffic conditions

- draft and formwork plans entirely derived from the 3D model

- use of the 3D model as basis for structural analysis

- use of the 3D model as basis for precise quantity definition

- use of the 3D model for three-dimensional lighting calculations

- use of the 3D model for workshop design of perforated sheets (around 230 different sheets due to the spatial bend)